A very effective type of adhesive used for securing metal pieces in industrial environments is a product called anaerobic flange sealant. This type of adhesive is well-known for its high strength and durability qualities, it means that the bond formed by this adhesion between two metal surfaces will be long-lasting. Read On To Learn More About The Benefits Of Anaerobic Flange Sealant And How It Can Drastically Improve Operational Performance, While Reducing Downtime.

They work by plugging the empty spaces between surfaces made of metal that are going to be attached. The sealant is in a liquid state when applied and only hardens upon exposure to metal. When the sealant reacts with metal, it cures causing adhesion to become hard and creating a strong bond between two surfaces. Anaerobic templates are called as such because they cure in the absence of air and when facing metal. "

Advanced flange sealant provides a solid, vibration-reducing surface that seals metal surfaces at the site of flanges and eliminates air from entering. It is used mostly in factories where constant stress and use on machines are experienced. It also adds to joint strength as well and helps increase the longevity of machinery or equipment.

Anaerobotic flange sealant has been proven beneficial for business in a number of aspects, one such is during the operations which it helps businesses to better manage their time and reduce downtime. Weak joints or seals can lead to equipment failures that are costly and take time out of production turnaround for repairs. Using anaerobic flange sealant as part of their reliable processes includes the creation of strong, stress-resistant joints to avoid failures.

Similarly anaerobic flange sealing will shorten its method time by lending a serving to hand of immediate curing. THE FACTORY ARRIVES AFTER ONE MONTH One month after the factory. The fast turnaround time allows companies to resume their business operations quickly, reducing downtimes due to equipment failure at a.minimum level

Anaerobic flange sealants enjoy such high performance because of the unusual chemistry behind these types of adhesive products. Anaerobic flange sealant curing process (makes adhesive to metal contact) Sealant hardens and fills gaps to create a bond between the metal surfaces that is capable of withstanding vibration and blows.

Also, the chemical composition of anaerobic flange sealant enables it to bond at molecular levels with metal surfaces. It yields in an almost unbreakable adhesive, more stronger than a typical glue. Without air and in the presence of metal, a non-aerobic flange sealant turns to an incredibly strong bonding agent.

Several factors have to be considered when choosing an anaerobic flange sealant for your business. Sealants come in various forms based on, Different variants of sealant are available to suit different applications meant for certain purposes.

Critical considerations in your evaluation are the metals being joined, temperature of operation for machinery or equipment and expected load conditions on joints. Selecting the proper anaerobic flange sealant for your particular application needs can save you time, money and prevent any gasket failures on extremed applications.

So, in short terms an anaerobic flange sealant is proven to be the best adhesive solution for all industrial applications. Anaerobic flange sealant closes the holes in between metal surfaces, so as to ensure a strong bond that last longer which increase joint strength and operational efficiency while minimizing equipment downtime. These sealants owe their adhesive strength to their chemistry which enables them to establish intimate bonding with metal surfaces making the resulting bond tough and vibration resistant. It may be difficult to do so, but choosing the right anaerobic flange sealant for you can ensure your assets stay in service and at peak performance.

Our customer service is thorough and professional We have a highly skilled customer service team who can resolve customer's problem effectively; the well-known customer service system as well as technical support help us offer the anaerobic flange sealant service to our customers

Haohai was established in the month of August 2000, has continued to maintain its rapid and steady growth trend. The company has also been designated an "anaerobic flange sealant and Civilized Unit in technological innovation" and has received ISO9001:2015 certificate for its quality system. Our products are of stable quality as we have a solid quality management system that is reliable and advanced equipment, along with a professional team.

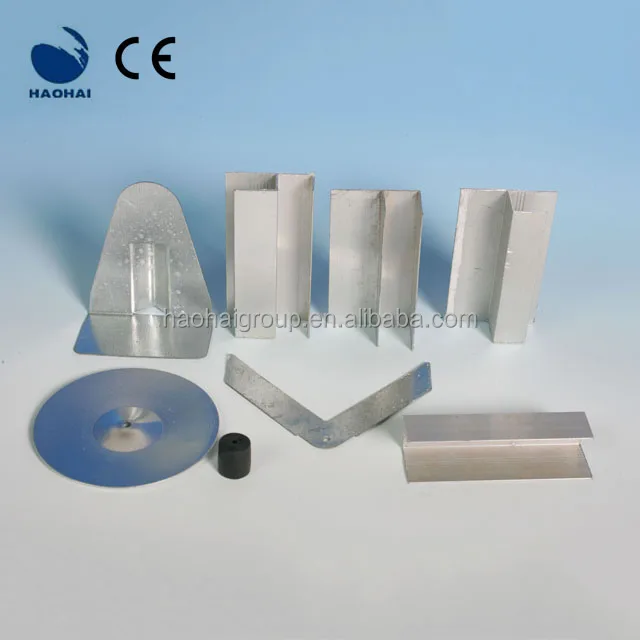

We offer a range of products like Duct Panels, PU Foam Stonefix adhesive foam Polystyrol spray adhesive, anaerobic flange sealant Adhesive Foam and aerosols for personal car care, personal care home care, auto care. We are now making OEM products for many well-known companies around the world.

Our products are made of the most durable anaerobic flange sealant Their quality and durability are higher than the competition and they have gained the respect of both domestic and international customers