Looking for how to laser cutting foam? I know, it sounds like such a load of hassle — but it is not as hard as you might think! In this article, I am going to show how laser technology can help cut foam and the reasons why lasercutting is a good way for different molding in things we love while cutting continuously with clean results — fast turnaround. Let’s dive in!

The word „laser“, might make people remember exiting movies, as well perhaps of cooler acreventures. Lasers on the other hand are useful for laser cutting things. How a laser cutter functions is that it projects an extremely potent beam of light in order to be able cut through materials like foam. One of the great things about laser cutting is the ability to have incredibly precise cuts that produce any sort of shape one desires. This means that you are able to create foam products in an array of sizing and custom shapes based on your specific needs. The best part? No matter what type of material you cut, the laser always leaves behind a clean and crisp cutting line with no chance for an untidy edge!

Foam can also be cut into special shapes with a laser cutter. Foam is a type of material that can be put for some different advantages in use such as seating, packaging things and so on. Note: foam is easy to damage if you do not take care when cutting it. However, using the laser process can really make your life easier to fabricate specific shapes. Foam for a comfy chair, foam insert in product box, with laser cutting you always get the right shape. Its a great way to make sure that your design looks exactly how you envisioned it.

Laser cutting foam is also extremely fast, one of the reasons it's such a neat process. It takes just a few seconds for the laser to cut through foam accurately and precisely; as such, you can form many shapes in little time. This is super great for businesses that have to produce foam products in large scale. Although done quickly, laser cutting quality remains very high. The laser provides a way to avoid rough edges, which gives foam look better and come across more professional in the eyes of your customers. No more uneven chops or jagged edges!

Foam Working — Perfect Laser Cut Irin however can be difficult to get the proper shape with other cutting methods as well because you foam may shift and move during says processes as we cut. However, since the laser is so precise it cuts the foam with no errors or shaking. This way you get what you want exactly, the same shape and size as it was created form your specifications. And because the laser cuts so cleanly, there is no need for sanding or other finishing processes afterwards. You can save time and effort!

Laser cutting may sound complicated, but it's actually quite simple to get started! Using a laser cutter requires no specific training or skill. You only have to set up the cut that you need for different shapes and leave it all on the laser. This makes it a perfect way to avoid having to fiddle with the foam and potentially even getting in trouble since the laser is so accurate. No matter how little or many foam products you need, laser cutting is a great choice for both small and large businesses.

Haohai founded in the month of laser cutting polyurethane foam, has maintained its fast and steady growth rate. The company has also been designated an "Advanced Enterprise and Civilized Unit in Technology Innovation" and has received ISO9001:2015 certification for its quality system. Our products are of high quality because we have a high-quality quality management system and the most advanced equipment and a highly skilled staff.

Our customer service is efficient and laser cutting polyurethane foam We have a skilled customer service team who can resolve any customer's issue efficiently The prominent customer service system and technical support ensure us to offer the highest quality service to our customers

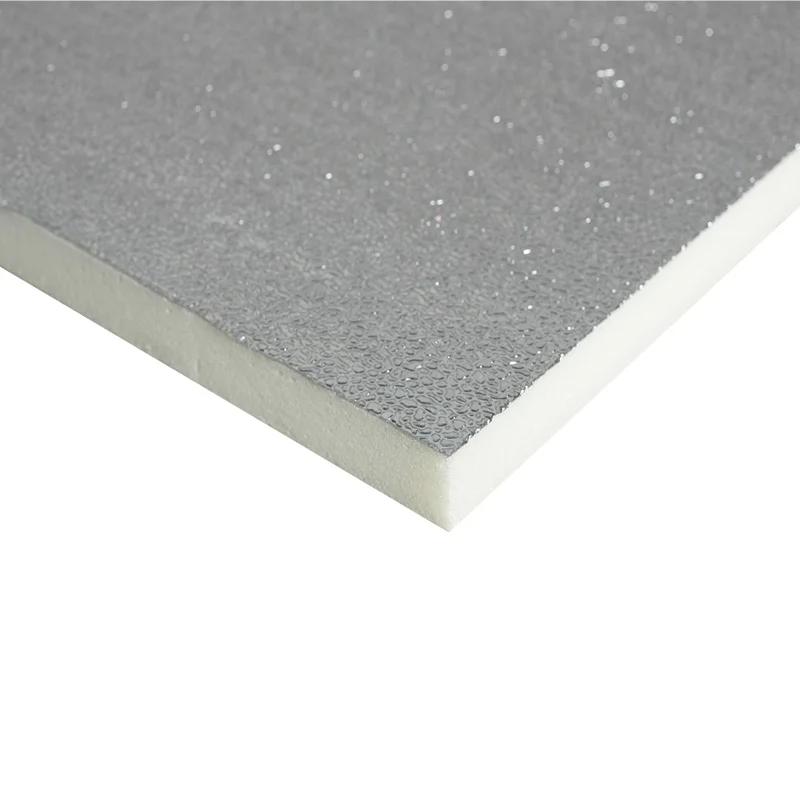

Our products are made with the top quality materials Their durability and performance are better than their laser cutting polyurethane foam and they have gained the trust of both domestic and international customers

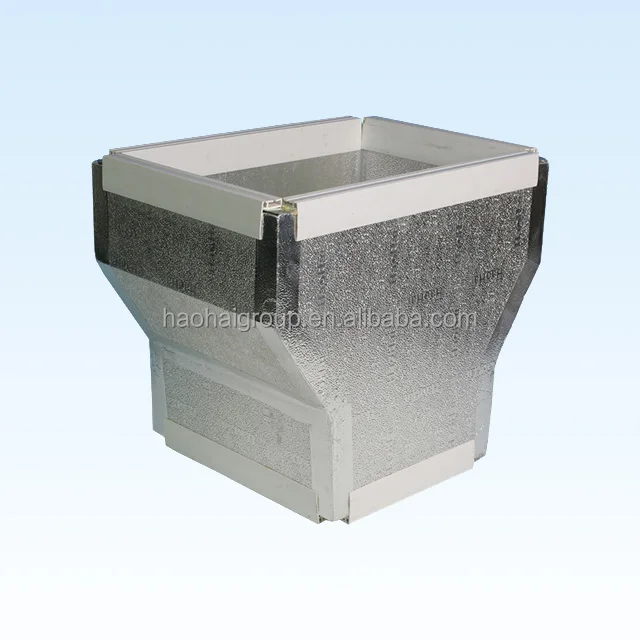

Our main products are Duct Panel, PU foam, stonefix adhesive foam, polystyrol adhesive foam, multipurpose spray adhesive foam and personal care and laser cutting polyurethane foam, as well as aerosols for car care. We are currently developing OEM products for renowned companies across the world.