pir panels are very cool building matericals that being made by our Haohai company. These panels are used in construction to help make buildings strong and insulated. This article is all about tonight's production process of pir sandwich panel!

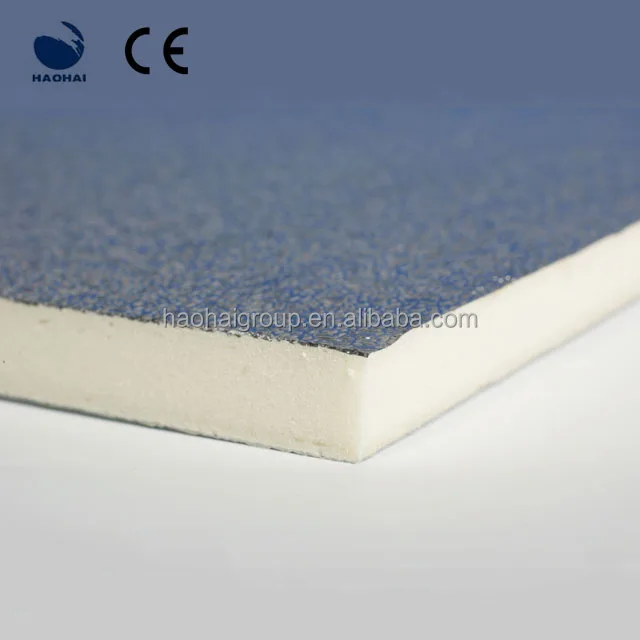

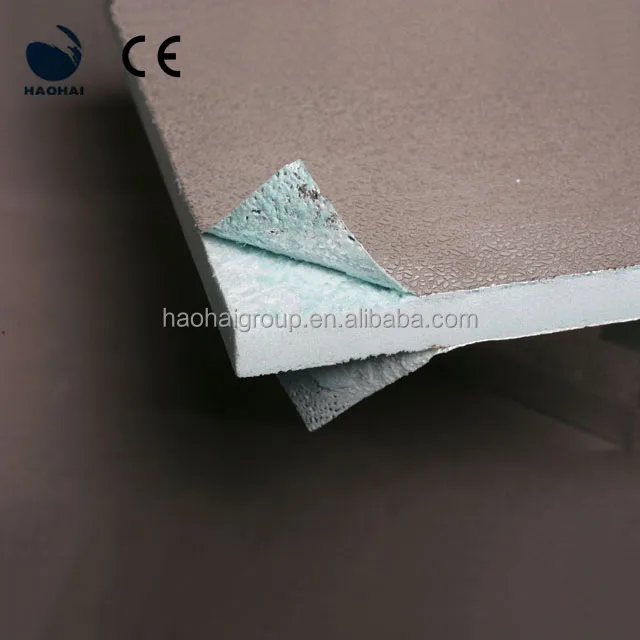

Making pir panels is much like being in a cool science experiment! Special chemicals are first combined to make a foam. This foam is then poured into a large mold and allowed to expand and cure. After the foam is formed, it is cut up in panels of various sizes. The panels are covered with a special material that makes them robust and sturdy.

There are several important steps in the production of the pir panels. To achieve the perfect consistency this foam mix is first meticulously prepared. The foam is then added to the mold and allowed to foam. From there, the panels are cut and covered to be ready to use. Every step is of concern so the pir panels can be high quality" peace of mind purchasing.

The process for manufacturing pir panels is a state-of-the-art! The foam ingredients are mixed using special machines and poured into the mold. These machines are highly accurate and ensure each panel is crafted perfectly. The coating process also includes state-of-the-art machinery that ensures the panels are durable and protected. Technology sure has made pir panel manufacturing and pir panel production the efficient process it is today!

There are many advantages to use of pir panels in building projects. These panels are incredibly tough and can withstand tough weather conditions. They are also natural insulators, helping to keep buildings warm in the winter and cool in the summer. Pir panels is weight is lightweight, easy to transport and instal. Construction with pir panels allows building to be done faster and more efficiently!

Haohai founded in the month of pir panel production, has maintained its fast and steady growth rate. The company has also been designated an "Advanced Enterprise and Civilized Unit in Technology Innovation" and has received ISO9001:2015 certification for its quality system. Our products are of high quality because we have a high-quality quality management system and the most advanced equipment and a highly skilled staff.

Our products are made with the top quality materials Their durability and performance are better than their pir panel production and they have gained the trust of both domestic and international customers

Our customer service is thorough and professional We have a highly skilled customer service team who can resolve customer's problem effectively; the well-known customer service system as well as technical support help us offer the pir panel production service to our customers

We manufacture a variety of products including Duct Panels, pir panel production, Stonefix adhesive foam, Polystyrol spray adhesive, Multipurpose Spray Adhesive, and aerosols for personal car care, personal care, homecare. We are now making OEM products for well-known corporations all over the world.