Polyurethane foam casting is an interesting and geeky method for crafting unique things from simple foam. This process is ideal for creative people that can imagine but one to be able to touch and see with their own eyes. In the fun way, liquid foam is poured into a mold (a container of special shape). Once the liquid foam enters and is poured into a mold, it then starts to expand, taking up all of said package shaping.

This technique works great when you want to make difficult or unique shapes that might be tough by other methods. We are able to let our fancy fly and design any conceivable shape. They can be more agile in producing new and different products as a result. After designing their foam product, they can review it and make any necessary adjustments or improvements to the design before being finalised for production. That means that your end product can be the best it needs to be!

Polyurethane foam casting is a widely preferred process by designers and manufacturers for the following reasons: There are so many advantages that one of the biggest is it saves a lot of money which you will get to know maybe later in this post. This process is both faster and requires less equipment than other model building methods. So as a result FAR less money goes into creating lots of foam prototypes. This is a huge benefit, as it means they can charge lower prices across the board making their purchases more accessible for everyone.

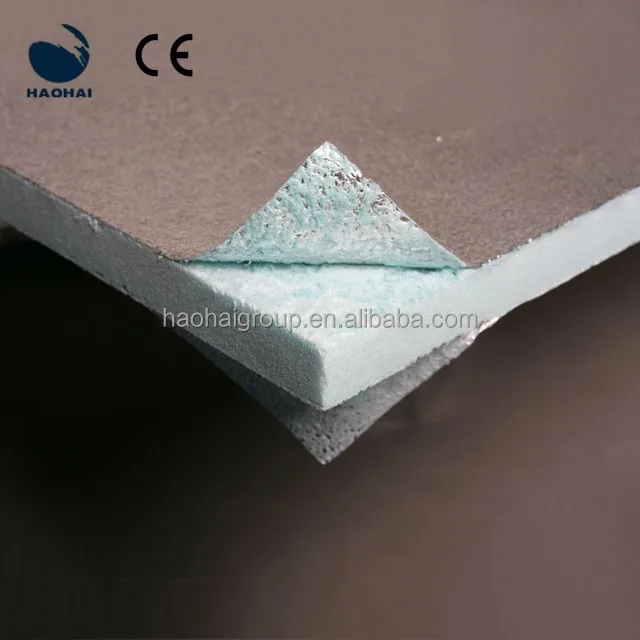

It is a real example of the rapid prototyping technology like Polyurethane foam casting that gives another shape and form to products in development. One of the really neat things is that this foam can be tailored to act like other materials, such as wood, metal or rubber. It is a great help for the designers and they can create products that are durable, moisture resistant as well as lightweight which certainly makes it one of its kind. This opens up a world of opportunity not only for manufacturing, but also to invent things that can be used in an array of scenarios.

Polyurethane Foam Casting — What Solution to Producing a Fast Delivery & Low-cost Manufactured Product? This means that manufacturers are able to make working sketches of their goods, which act like a practice version of what the final item will look like. These models work to expedite the product, time-to-market. And that also allow to iteration on Design very rapid, so we can catch any mistake or fault early. This can be done in order to refine and perform the final version of a product before releasing it for an average user.

All of our products are manufactured using the finest quality materials They outperform their competitors when it comes to durability and performance They are highly regarded by both polyurethane foam casting

Our primary products include polyurethane foam casting, PU foam, Stonefix adhesive foam, polystyrol adhesive foam multi-purpose spray adhesive foam as well as personal care, home care, aerosols for car care. We are now creating OEM products for renowned companies across the world.

Haohai founded in the month of polyurethane foam casting, has maintained its fast and steady growth rate. The company has also been designated an "Advanced Enterprise and Civilized Unit in Technology Innovation" and has received ISO9001:2015 certification for its quality system. Our products are of high quality because we have a high-quality quality management system and the most advanced equipment and a highly skilled staff.

Our customer service is thorough and professional We have a professional customer service team that can solve any customer's issue efficiently The well-known customer service system as well as polyurethane foam casting allow us to give the best service to our clients