Back in the day, all they did with their used foam was dump it. They would just end up tossing it, and then that waste would sit in dumps for quite some time - sometimes decades! Or in other words, the old foam just sitting there doing nothing for anyone. But now, we have a new kid on the block in terms of foam — recycled polyurethane foam.

Recycled polyurethane foam: Lots of people like the idea that they can help save the planet with their purchase and make it a great place to live in. Old foam removed becomes non-biodegradable, and so the damage it does to our world lasts for some time. Then, recycled foam is cool because it can be utilised over and over in a forever circle! This keeps more garbage from going to the landfill and means less polluting our planet.

Repurposing used foam is a good idea because it helps keep the material out of landfills, and turns what would have been waste into an asset. Businesses can take old foam and use it to create a number of other soft goods, including: cushions for chairs carpet padding (so your carpets feel better) soundproofing products (that help you block noise out rather than in). That is to say, old foam can be re-used in new items and scrap out of sight!

An excellent manner to guard our planet and keep it healthful is through the use of recycled foam. Recycled foam saves energy and reduces end waste when compared to new foams with the aim of reducing their carbon footprints. This is really good news for everyone as it helps in the reduction of pollution and keeps our air and water cleaner. A double win for the environment and us who lives within it!

There are many advantages to using all of that recycled foam in the manufacture of new products. It helps the environment from two main ways, first off it reduces waste and saves energy that would have been used producing more raw material. The fact that recycled foam also costs less than buying new foam to produce is but a second reason; companies avoid the expensive of mining or drilling up fresh materials from beneath the earth. The best part is it functions as the new foam would, so businesses can justifiably rely on that their items are in acceptable control to maintain a strategic distance from any merchandise disappointments.

The answer is that recycled polyurethane foam was first developed in the 1990s by Cargill Dow. They wanted to create sustainable plastics, and they thought of recycling foam. This was a big breakthrough! As we know that the environment is a dangerous situation nowadays, this has meant many companies want to demonstrate what responsible measures they put into consideration before taking it as an moral responsibility before making any product today.

Haohai founded in the month of recycled polyurethane foam, has maintained its fast and steady growth rate. The company has also been designated an "Advanced Enterprise and Civilized Unit in Technology Innovation" and has received ISO9001:2015 certification for its quality system. Our products are of high quality because we have a high-quality quality management system and the most advanced equipment and a highly skilled staff.

Our products are manufactured using the top quality materials They recycled polyurethane foam their competitors in terms of strength and performance They are highly regarded by both foreign and domestic customers

Our customer service is recycled polyurethane foam and attentive Our customer service team is competent to solve customer's issues The prominent customer service system and technical support allows us to deliver a top-quality service

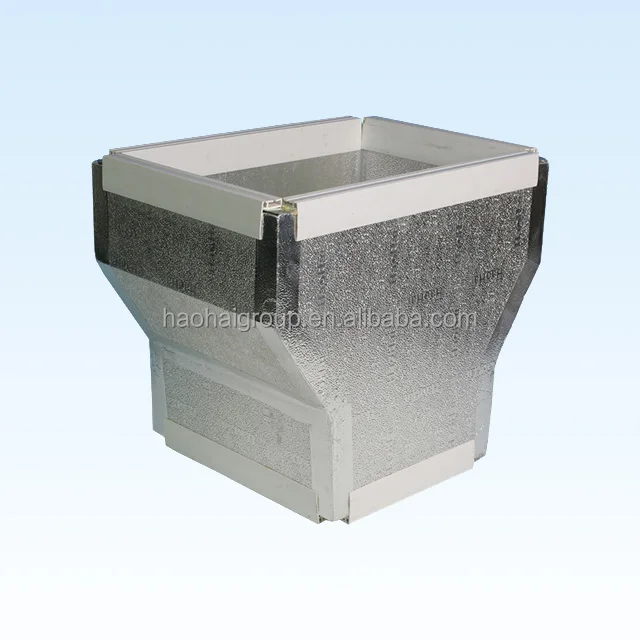

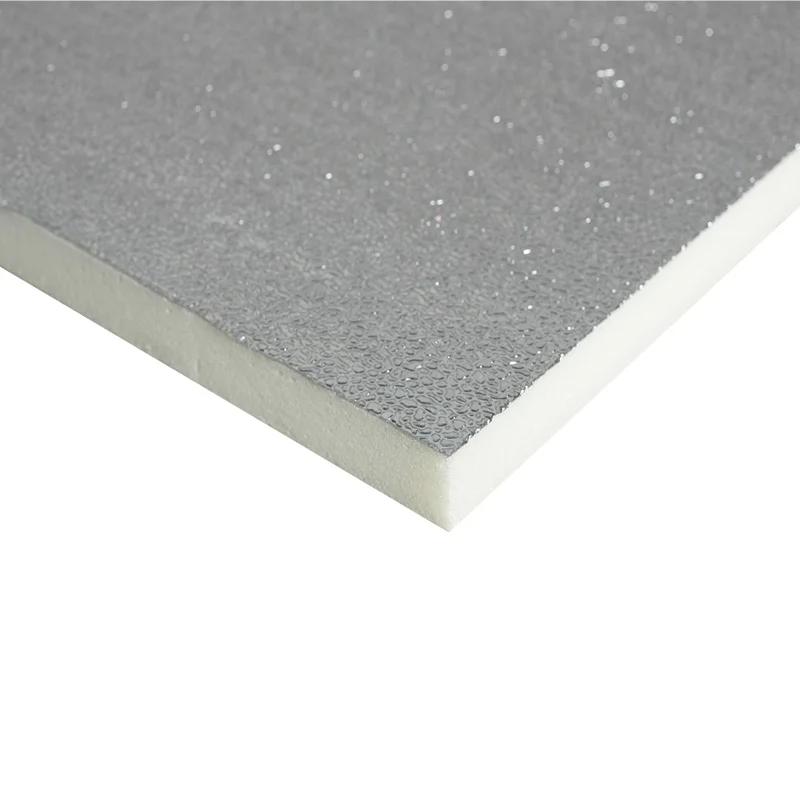

Our most popular products are Duct Panel, PU foam and stonefix adhesive foam, polystyrol foam multipurpose spray adhesive foam and personal care such as home care, aerosols for car care. Today, we are developing recycled polyurethane foam for a variety of well known companies around the world.