One of the materials associated with being a super material is rigid polyurethane foam. The island is made up of tiny bubbles and therefore, very light to move around. This article will expose many of the benefits, how it works and where you may find applications as well few things to consider when using this material.

Strength One of the major pros of rigid polyurethane foam is its strength. That makes it valuable as a form of insulation, which is crucial because that helps keep buildings warm in the winter and cool in the summer. It is a foam that can be used in houses and to make specific products, such as boats or surfboards where the form needs to support peoples weights. The light part of the rigid polyurethane foam is also good. This lightness of silicones makes it very easy to handle and work with, as well as helps the final product from not being overly heavy (which is really good for things like boats or anything that you need its moved around.)

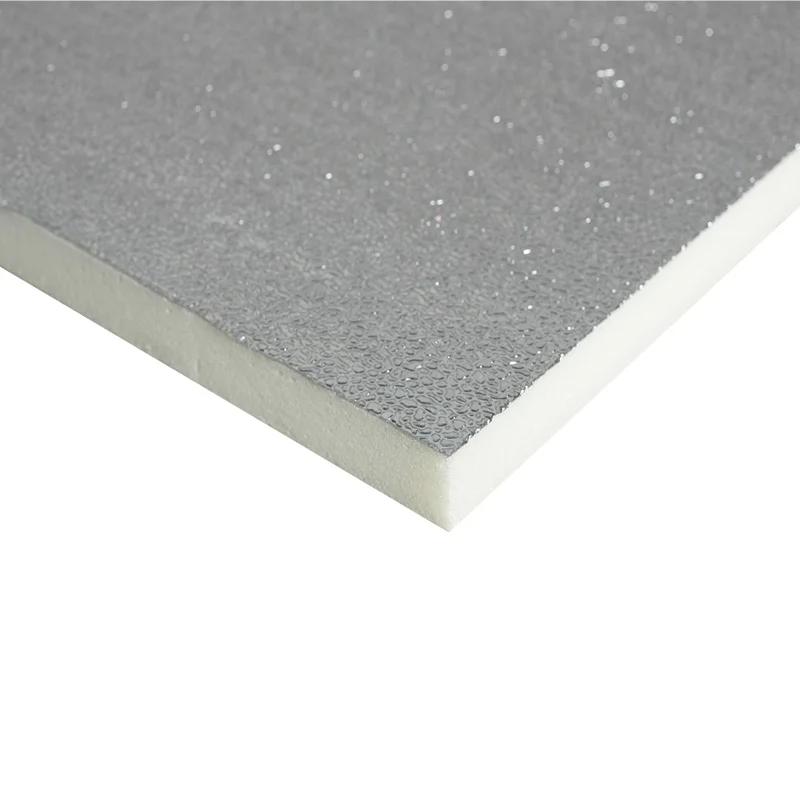

Well then, let us help you guys out a little bit more by breaking down how the product that we are dependent on is made in its simplest form — rigid polyurethane foam. This necessitates combining two different chemicals. The chemical that reacts with the gas in another to froth is fashion from such a gas. The foam subsequently inflates into the location it is in, which is a very neat procedure. As the foam cures it dries, thus curing into its hard form that gives Polyurethane Foam strength. It is truly fascinating how, to the touch these small pockets of air won´t be noticeable at all and yet this very similar foam acts as thermal insulation making things warm or cool depending on whether you´re using it. Well, that also means it gives some strength to the piece, and jouj can be used for temperature control prostitutions as well.

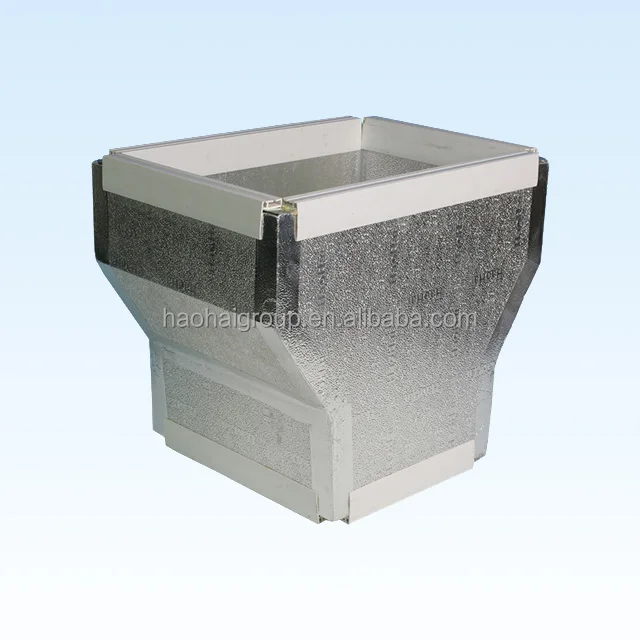

Rigid polyurethane foam has many the different areas used regarding wide functions. Typically, it is used as an insulation material in buildings. It can be sprayed into walls or ceilings where it expands and fills the void. This makes it a good barrier to prevent heat loss, which is particularly beneficial in cold climates. It is also used in packaging materials. An instance where this foam is utilized to ensure that fragile items do not break during the transport. Because of this characteristic, you will often find rigid polyurethane foam in things like boats and surfboards to prevent water damage and still have a lightweight material. Furthermore, it is a common inhabitant of our refrigerators and freezer that helps us to keep our food fresh and the temperature optimal.

This blog post provides a few important safety tips to remember when working with rigid polyurethane foam. One, it can be dangerous if you do not take care to handle it correctly - so always wear gloves and protective clothing. Thus it will protect you from harmful effects. The foam dries quite hard and therefore is a bugger to clean off again, so plan out your finish before you apply the stuff. Additionally, if the foam is not applied in a sufficient quantity it may have limited efficacy leaving you high and dry with some of those costly issues later on. By being cautious if you do set things up and plan ahead, the foam should behave as expected.

Rigid polyurethane foam is made by the reaction of two main chemicals which are blended together, namely; Polyol and Diisocyanate. When this two chemicals mix, they react to each other and form foam. This reaction releases carbon dioxide and hence the foam bubbles. These...bubbles are critical because they keep foam light and fluffy.

A convenient feature of rigid polyurethane foam is that it has a closed-cell structure ( Your browser does not support this video. In other words, water and air are not able to pass through the foam. Hence, making it a perfect option to insulate as heat cannot pass through cellophane easily. In addition, the closed-cell structure provides high strength so this foam bears a lot of weight and it does not get crushed or damaged.

Our primary products include Duct Panel, PU foam, rigid polyurethane foam, polystyrol foam, multi-purpose spray adhesive foam as well as personal care such as home care, car care aerosols. We are currently developing OEM products for well-known firms across the globe.

Our service is prompt and observant We have a professional customer rigid polyurethane foam that can solve problems for customers efficiently; our popular customer service system and technical support help us supply perfect service to our customers

Our products are constructed using most durable materials They surpass their rigid polyurethane foam when it comes to endurance and performance They are highly regarded by both domestic and foreign customers

Haohai founded in the month of rigid polyurethane foam, has maintained its fast and steady growth rate. The company has also been designated an "Advanced Enterprise and Civilized Unit in Technology Innovation" and has received ISO9001:2015 certification for its quality system. Our products are of high quality because we have a high-quality quality management system and the most advanced equipment and a highly skilled staff.