Construction system consisting of sandwich panels. These panels consist of various layers that are glued together to produce a solid durable panel. The sandwich panels are becoming very popular in construction and can contribute to enhancing building energy efficiency. Let’s explore the elements of this type of sandwich panel now to understand how they can be employed in green building.

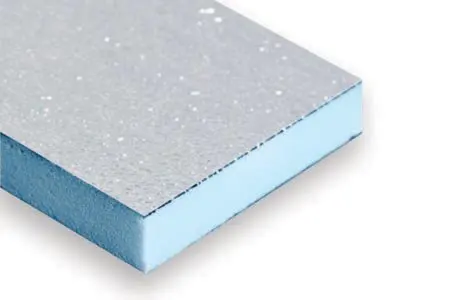

A sandwich panel consists of three principal constituents: a core material, two face sheets, and a layer of adhesive. It typically consists of lightweight and thermally insulated materials like polystyrene, polyurethane, or rock wool. Face sheets are typically constructed from relatively hard and strong materials such as steel, aluminum, and fiberglass. The adhesive is employed to bond the core and the face sheets together such that the panel becomes monolithic.

One of the primary means by which sandwich panels contribute to energy efficiency within buildings is their ability to serve as insulation material. The fillings of sandwich panels are good insulators, which can help to keep the buildings warm in winter and cool in summer. That in turn could potentially save money on energy costs, if it lessens the need for energy to heat and cool buildings.

Moreover, sandwich panels can also contribute to improving the energy efficiency of buildings and achieve air tightness. The airtight seal formed by sandwich panels can prevent air from escaping from buildings, allowing buildings to maintain their temperature. This can potentially lessen the load on heating and cooling systems, helping to save energy, and lower you carbon emissions.

Use38783 mm, Use8 insandwich panels are flexible in the way they can be used and are suitable for both cold and hot carrying roofs and walls. They are also used to make walls, roofs, floors and ceilings and can be tailored to any project requirements QPainter. Sandwich panels can also be combined with other building materials, such as glass and wood, to create new and modern designs.

One more benefit of sandwich panels meant for design and constructing is the simplicity in their handling. With their versatility, sandwich panels can be cut, bent, folded and shaped to suit any architectural design, making them ideal for use in a number of applications. Sandwich panels are also offered in different colors and finishes, also allowing for nice designs and good looks.

Sandwich panels play an important role in environmentally friendly construction. The lightweight construction and their good thermal insulation performance make sandwich panels ideal for the saving of energy in buildings, thus reduce carbon emissions and alleviate the impact on the climate system. Besides, sandwich panels are durable and can stand the test of time, so to speak, lessening the need for repairs and replacements, and in turn lessening waste and promoting sustainability.

Our customer service is thorough and professional We have a highly skilled customer service team who can resolve customer's problem effectively; the well-known customer service system as well as technical support help us offer the sandwich panels construction service to our customers

sandwich panels construction its beginning from August, 2000 Haohai has maintained its steady and rapid growth trend. It has now become a "Advanced Enterprise and Civilized Unit for technological innovation" as well as obtaining the ISO9001:2015 certification for quality systems. The secure quality management system as well as the modern equipment and experienced staffs make our products with stable quality.

Our products are constructed using sandwich panels construction durable materials Their endurance and performance is superior to those of their competitors and they have gained the confidence of both domestic and international clients

Our main products are Duct Panel, PU foam, stonefix adhesive foam, polystyrol adhesive foam, multipurpose spray adhesive foam and personal care and sandwich panels construction, as well as aerosols for car care. We are currently developing OEM products for renowned companies across the world.