Pěna PU, zkratka za polyuretanovou pěnu, nezní příliš vzrušujícím dojmem. Je však nekonečně užitečným materiálem, který hraje velkou roli v kompozitních a sendvičových deskách. Přední výrobce odvětví Haohai využívá hodnotu pěny PU s inovativními řešeními téměř pro každé použití. Jedním z neobvyklých způsobů využití pěny PU v kompozitních / sendvičových deskách a důvodem, proč je Haohai v čele?

Vhodnost pěny PU pro kompozitní a sendvičové desky

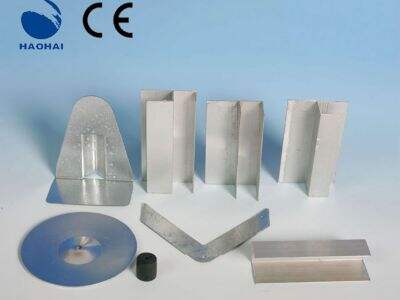

Ve společnosti Haohai hraje polyuretanová pěna v kompozitních a sendvičových deskách hvězdnou roli díky svým speciálním vlastnostem. Polyuretanová pěna je lehká, trvanlivá a velmi dobře tvarovatelná, což ji činí ideálním materiálem pro výrobu detailních forem. Navíc disponuje vynikající tepelnou a akustickou izolací, a proto se často používá v aplikacích vyžadujících kontrolu teploty a zvuku. Ať už jde o stavebnictví, automobilový průmysl nebo námořní aplikace, flexibilita polyuretanové pěny ji činí preferovanou volbou pro kompozitní a sendvičové desky.

Za druhé, zvyšování strukturální pevnosti kompozitů z polyuretanové pěny

Díky kombinaci velký špachtlecí pěnový náplňák použitím kompozitů může Haohai posílit konstrukci mnoha výrobků. Pěnové polyurethanové (PU) hmoty slouží jako jádrový materiál, který zpevňuje kompozitní strukturu, a přitom pěnění umožňuje dosáhnout vyšší odolnosti a nárazové pevnosti. To je velmi užitečné v odvětvích, kde záleží na pevnosti a odolnosti, například v leteckém nebo námořním stavitelství. Kromě toho nabízejí kompozity s PU pěnou širokou flexibilitu v návrhu, což umožňuje vyrábět komponenty s nízkou hmotností, které jsou zároveň pevné.

Optimalizujte izolaci a energetickou účinnost pomocí sendvičových panelů z PU pěny

Sendvičová deska z pěnového PU je novým trendem ve stavební strategii, který díky tomuto typu produktu přispívá k šetrnějšímu prostředí. Tyto desky se skládají z jádra z pěnového PU, které je uloženo mezi dvěma povrchovými vrstvami, například kovem nebo sklolaminátem. Izolační účinek pěnového PU snižuje spotřebu energie a tím i náklady na vytápění. Sendvičové desky z pěnového PU od společnosti Haohai jsou navrženy s ohledem na energetickou účinnost a mohou nabízet vynikající odolnost, dlouhou životnost a zároveň atraktivní vzhled.

Řešení z pěnového PU pro lehké a odolné konstrukce

Lehkost Nejdůležitější výhodou stavební pěna je její nízká hmotnost, díky níž je vhodná pro aplikace, u nichž může úspora hmotnosti významně pomoci. Aplikace pěnového PU od společnosti Haohai poskytují ideální kombinaci nízké hmotnosti a odolnosti pro většinu průmyslových odvětví. Ať už jde o lehké automobilové díly nebo pevné námořní konstrukce, pěnové PU od Haohai Vám poskytuje pevnost bez zbytečné hmotnosti.

Odemkněte si cenově dostupná a udržitelná řešení s technologií pěnového PU

Dnes je udržitelnost výrobního procesu klíčovou otázkou. Technologie pěny PU od společnosti haohai může být nízkonákladovým a ekologickým řešením pro mnoho aplikací. Díky nízké spotřebě energie při výrobě pěny PU může haohai pomoci spotřebitelům snížit zátěž životního prostředí. Ať už jde o recyklaci odpadu ve výrobním procesu, nebo o stavbu energeticky úsporných budov: technologie pěny PU vede k čistší budoucnosti.

Závěr

Mnohé aplikace pěny PU ve skladebných materiálech a sendvičových konstrukcích jsou nepřehlédnutelné. Přínos inovativní aplikace diy rozpínací pěna poskytla průmyslu nekonečné možnosti, jak zlepšit pevnost, tepelnou izolaci a lehkou konstrukci u svých produktů s ohledem na udržitelnost. Pěny PU od haohai posouvají průmysl na novou technologickou úroveň. Jako průmyslový lídr vyvíjí haohai profesionální aplikace pěn PU a představuje tak inovace i udržitelnost pro své výrobní zákazníky.

Obsah

- Vhodnost pěny PU pro kompozitní a sendvičové desky

- Za druhé, zvyšování strukturální pevnosti kompozitů z polyuretanové pěny

- Optimalizujte izolaci a energetickou účinnost pomocí sendvičových panelů z PU pěny

- Řešení z pěnového PU pro lehké a odolné konstrukce

- Odemkněte si cenově dostupná a udržitelná řešení s technologií pěnového PU

- Závěr

EN

EN